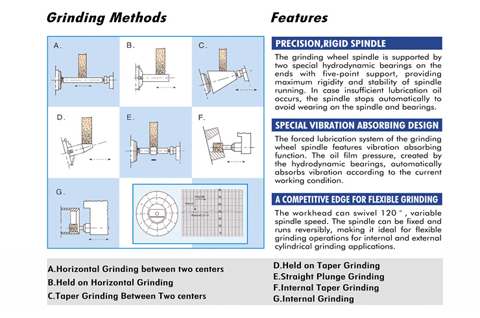

Description of constructionAll cast machine parts are made of high quality certified cast iron stand has a hexagonal ribs to ensure high rigidity. Iron castings are 2 brindle with emphasis on the elimination of all metallurgical stress.Grinding spindle is placed in 2 special hydrodynamic bearings with five dot support at both ends, which makes them no dilatacím heat, vibration and wear and spindle can operate at high speeds, long term and stable. Vibration damping system during machining is also supported by strong lubrication system which also has the function of vibration damping. The pressure generated by hydrodynamic oil film bearings absorb vibration under current working conditions of spindle is equipped with an automatic lubrication condition diagnosis, insufficient lubrication of the spindle will automatically stop, so as to avoid unnecessary wear and spindle bearings. All against surfaces are lined with special sliding material Turcite-B, this is achieved nearly zero coefficient of friction. The surface of the guide surfaces table and the headstock is hand zaškrabán, thereby ensuring high accuracy and to achieve the perfect seating pattern between the contact surfaces. High rigidity musculoskeletal, heavy-duty table and the lowest possible value of the deformation and twist - all guaranteed to achieve maximum productivity with high quality cut surface and permanent accuracy.  |